红外相关知识

发射率指导表

了解目标的发射率,或者它的"辐射"特性,这是红外测量的关键构成。简单地说,发射率就是一个表面或者黑体发出的辐射的比率,它的辐射理论由普朗克的定律预测. [宽(L,T)=C1/(L^5*(exp(C2/LT当直接观察一种材料表面的发射率就是表面大量的能源的测量。有很多因素影响具体目标的发射率,例如波长,视野,黑体的几何形状,以及温度。然而,对于红外测温仪使用者的目的和应用来说,更希望得到一张全面反映发射率在各种各样的物体表面和目标上的相应温度的表。有关发射率更详细的技术说明,请直接与ZyTemp联系.

非金属

| 材料(非金属) |

Temp degF(degC) |

Emissivity |

| Adobe |

68 (20) |

0.9 |

| Asbestos |

| ˇˇ |

Board |

100 (38) |

0.96 |

| ˇˇ |

Cement |

32-392

(0-200) |

0.96 |

| ˇˇ |

Cement, Red |

2500

(1371) |

0.67 |

| ˇˇ |

Cement, White |

2500 (1371) |

0.65 |

| ˇˇ |

Cloth |

199 (93) |

0.9 |

| ˇˇ |

Paper |

100-700

(38-371) |

0.93 |

| ˇˇ |

Slate |

68 (20) |

0.97 |

| ˇˇ |

Asphalt, pavement |

100 (38) |

0.93 |

| ˇˇ |

Asphalt, tar paper |

68 (20) |

0.93 |

| Basalt |

68 (20) |

0.72 |

| Brick |

| ˇˇ |

Red,

rough |

70 (21) |

0.93 |

| ˇˇ |

Gault

Cream |

2500-5000

(1371-2760) |

.26-.30 |

| ˇˇ |

Fire Clay |

2500 (1371) |

0.75 |

| ˇˇ |

Light Buff |

1000 (538) |

0.8 |

| ˇˇ |

Lime Clay |

2500

(1371) |

0.43 |

| ˇˇ |

Fire

Brick |

1832

(1000) |

.75-.80 |

| ˇˇ |

Magnesite,

Refractory |

1832

(1000) |

0.38 |

| ˇˇ |

Grey

Brick |

2012

(1100) |

0.75 |

| ˇˇ |

Silica, Glazed |

2000

(1093) |

0.88 |

| ˇˇ |

Silica, Unglazed |

2000

(1093) |

0.8 |

| ˇˇ |

Sandlime |

2500-5000

(1371-2760) |

.59-.63 |

| Carborundum |

1850 (1010) |

0.92 |

| Ceramic |

| ˇˇ |

Alumina on

Inconel |

800-2000

(427-1093) |

.69-.45 |

| ˇˇ |

Earthenware, Glazed |

70 (21) |

0.9 |

| ˇˇ |

Earthenware, Matte |

70 (21) |

0.93 |

| ˇˇ |

Greens No. 5210-2C |

200-750 (93-399) |

.89-.82 |

| ˇˇ |

Coating No.

C20A |

200-750 (93-399) |

.73-.67 |

| ˇˇ |

Porcelain |

72 (22) |

0.92 |

| ˇˇ |

White

Al2O3 |

200 (93) |

0.9 |

| ˇˇ |

Zirconia on

Inconel |

800-2000

(427-1093) |

.62-.45 |

| Clay |

68 (20) |

0.39 |

| ˇˇ |

Fired |

158 (70) |

0.91 |

| ˇˇ |

Shale |

68

(20) |

0.69 |

| ˇˇ |

Tiles, Light

Red |

2500-5000

(1371-2760) |

.32-.34 |

| ˇˇ |

Tiles,

Red |

2500-5000

(1371-2760) |

.40-.51 |

| ˇˇ |

Tiles,Dark Purple |

2500-5000

(1371-2760) |

0.78 |

| Concrete |

| ˇˇ |

Rough |

32-2000

(0-1093) |

0.94 |

| ˇˇ |

Tiles, Natural |

2500-5000

(1371-2760) |

.63-.62 |

| ˇˇ |

Brown |

2500-5000

(1371-2760) |

.87-.83 |

| ˇˇ |

Black |

2500-5000

(1371-2760) |

.94-.91 |

| Cotton Cloth |

68 (20) |

0.77 |

| Dolomite

Lime |

68 (20) |

0.41 |

| Emery Corundum |

176 (80) |

0.86 |

| Glass |

| ˇˇ |

Convex D |

212

(100) |

0.8 |

| ˇˇ |

Convex D |

600

(316) |

0.8 |

| ˇˇ |

Convex D |

932

(500) |

0.76 |

| ˇˇ |

Nonex |

212

(100) |

0.82 |

| ˇˇ |

Nonex |

600

(316) |

0.82 |

| ˇˇ |

Nonex |

932

(500) |

0.78 |

| ˇˇ |

Smooth |

32-200(0-93) |

.92-.94 |

| Granite |

70 (21) |

0.45 |

| Gravel |

100 (38) |

0.28 |

| Gypsum |

68 (20) |

.80-.90 |

| Ice,

Smooth |

32 (0) |

0.97 |

| Ice,

Rough |

32 (0) |

0.98 |

| Lacquer |

| ˇˇ |

Black |

200 (93) |

0.96 |

| ˇˇ |

Blue, on Al

Foil |

100 (38) |

0.78 |

| ˇˇ |

Clear, on Al Foil (2

coats) |

200 (93) |

.08-.09 |

| ˇˇ |

Clear, on Bright

Cu |

200 (93) |

0.66 |

| ˇˇ |

Clear, on Tarnished

Cu |

200 (93) |

0.64 |

| ˇˇ |

Red, on Al Foil (2

coats) |

100 (38) |

.60-.74 |

| ˇˇ |

White |

200 (93) |

0.95 |

| ˇˇ |

White, on Al Foil (2

coats) |

100 (38) |

.69-.88 |

| ˇˇ |

Yellow, on Al Foil

(2 coats) |

100 (38) |

.57-.79 |

| Lime

Mortar |

100-500

(38-260) |

.90-.92 |

| Limestone |

100 (38) |

0.95 |

| Marble, White |

100 (38) |

0.95 |

| ˇˇ |

Smooth, White |

100 (38) |

0.56 |

| ˇˇ |

Polished Grey |

100 (38) |

0.75 |

| Mica |

100 (38) |

0.75 |

| Oil on

Nickel |

| ˇˇ |

0.001 Film |

72 (22) |

0.27 |

| ˇˇ |

0.002 " |

72 (22) |

0.46 |

| ˇˇ |

0.005 " |

72 (22) |

0.72 |

| ˇˇ |

Thick " |

72 (22) |

0.82 |

| Oil,

Linseed |

| ˇˇ |

On Al Foil,

uncoated |

250

(121) |

0.09 |

| ˇˇ |

On Al Foil, 1 coat |

250

(121) |

0.56 |

| ˇˇ |

On Al Foil, 2 coats |

250

(121) |

0.51 |

| ˇˇ |

On Polished Iron,

.001 Film |

100 (38) |

0.22 |

| ˇˇ |

On Polished Iron,

.002 Film |

100 (38) |

0.45 |

| ˇˇ |

On Polished Iron,

.004 Film |

100 (38) |

0.65 |

| ˇˇ |

On Polished Iron,

Thick Film |

100 (38) |

0.83 |

| Paints |

| ˇˇ |

Blue, Cu2O3 |

75 (24) |

0.94 |

| ˇˇ |

Black, CuO |

75 (24) |

0.96 |

| ˇˇ |

Green,

Cu2O3 |

75 (24) |

0.92 |

| ˇˇ |

Red, Fe2O3 |

75 (24) |

0.91 |

| ˇˇ |

White,

Al2O3 |

75 (24) |

0.94 |

| ˇˇ |

White, Y2O3 |

75 (24) |

0.9 |

| ˇˇ |

White, ZnO |

75 (24) |

0.95 |

| ˇˇ |

White, MgCO3 |

75 (24) |

0.91 |

| ˇˇ |

White, ZrO2 |

75 (24) |

0.95 |

| ˇˇ |

White, ThO2 |

75 (24) |

0.9 |

| ˇˇ |

White, MgO |

75 (24) |

0.91 |

| ˇˇ |

White, PbCO3 |

75 (24) |

0.93 |

| ˇˇ |

Yellow, PbO |

75 (24) |

0.9 |

| ˇˇ |

Yellow, PbCrO4 |

75 (24) |

0.93 |

| Paints, Aluminium |

100 (38) |

.27-.67 |

| ˇˇ |

10% Al |

100 (38) |

0.52 |

| ˇˇ |

26% Al |

100 (38) |

0.3 |

| ˇˇ |

Dow XP-310 |

200 (93) |

0.22 |

| Paints, Bronze |

Low |

.34-.80 |

| ˇˇ |

Gum Varnish (2

coats) |

70 (21) |

0.53 |

| ˇˇ |

Gum Varnish (3

coats) |

70 (21) |

0.5 |

| ˇˇ |

Cellulose Binder (2

coats) |

70 (21) |

0.34 |

| Paints,

Oil |

| ˇˇ |

All colours |

200 (93) |

.92-.96 |

| ˇˇ |

Black |

200 (93) |

0.92 |

| ˇˇ |

Black Gloss |

70 (21) |

0.9 |

| ˇˇ |

Camouflage

Green |

125 (52) |

0.85 |

| ˇˇ |

Flat Black |

80 (27) |

0.88 |

| ˇˇ |

Flat White |

80 (27) |

0.91 |

| ˇˇ |

Grey-Green |

70 (21) |

0.95 |

| ˇˇ |

Green |

200 (93) |

0.95 |

| ˇˇ |

Lamp Black |

209 (98) |

0.96 |

| ˇˇ |

Red |

200 (93) |

0.95 |

| ˇˇ |

White |

200 (93) |

0.94 |

| Quartz, Rough,

Fused |

70 (21) |

0.93 |

| ˇˇ |

Glass, 1.98 mm |

540 (282) |

0.9 |

| ˇˇ |

Glass, 1.98

mm |

1540 (838) |

0.41 |

| ˇˇ |

Glass, 6.88 mm |

540

(282) |

0.93 |

| ˇˇ |

Glass, 6.88 mm |

1540

(838) |

0.47 |

| ˇˇ |

Opaque |

570

(299) |

0.92 |

| ˇˇ |

Opaque |

1540 (838) |

0.68 |

| Red Lead |

212 (100) |

0.93 |

| Rubber, Hard |

74 (23) |

0.94 |

| Rubber, Soft, Grey |

76 (24) |

0.86 |

| Sand |

68

(20) |

0.76 |

| Sandstone |

100 (38) |

0.67 |

| Sandstone, Red |

100 (38) |

.60-.83 |

| Sawdust |

68 (20) |

0.75 |

| Shale |

68 (20) |

0.69 |

| Silica,Glazed |

1832

(1000) |

0.85 |

| Silica, Unglazed |

2012 (1100) |

0.75 |

| Silicon

Carbide |

300-1200 (149-649) |

.83-.96 |

| Silk

Cloth |

68 (20) |

0.78 |

| Slate |

100 (38) |

.67-.80 |

| Snow, Fine

Particles |

20 (-7) |

0.82 |

| Snow, Granular |

18 (-8) |

0.89 |

| Soil |

| ˇˇ |

Surface |

100 (38) |

0.38 |

| ˇˇ |

Black Loam |

68 (20) |

0.66 |

| ˇˇ |

Plowed Field |

68 (20) |

0.38 |

| Soot |

| ˇˇ |

Acetylene |

75 (24) |

0.97 |

| ˇˇ |

Camphor |

75 (24) |

0.94 |

| ˇˇ |

Candle |

250

(121) |

0.95 |

| ˇˇ |

Coal |

68 (20) |

0.95 |

| Stonework |

100 (38) |

0.93 |

| Water |

100 (38) |

0.67 |

| Waterglass |

68 (20) |

0.96 |

| Wood |

Low |

.80-.90 |

| Beech Planed |

158 (70) |

0.94 |

| Oak, Planed |

100 (38) |

0.91 |

| Spruce,

Sanded |

100 (38) |

0.89 |

|

|

|

|

|

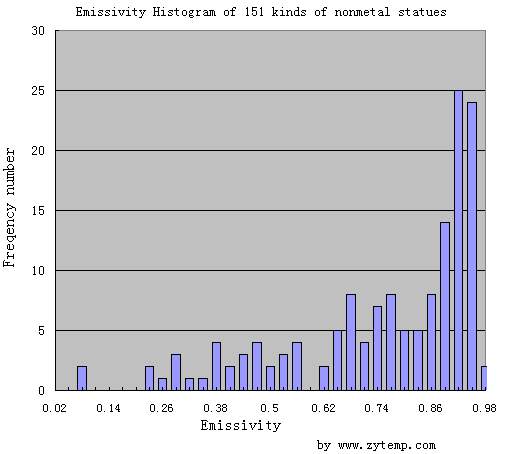

非金属EMS直方图

金属

| Material(metal) |

Temp

degF (degC) |

Emissivity |

| Alloys |

| ˇˇ |

20-Ni,

24-CR, 55-FE, Oxid. |

392

(200) |

0.9 |

| ˇˇ |

20-Ni,

24-CR, 55-FE, Oxid. |

932(500) |

0.97 |

| ˇˇ |

60-Ni,

12-CR, 28-FE, Oxid. |

518

(270) |

0.89 |

| ˇˇ |

60-Ni,

12-CR, 28-FE, Oxid. |

1040

(560) |

0.82 |

| ˇˇ |

80-Ni,

20-CR, Oxidised |

212

(100) |

0.87 |

| ˇˇ |

80-Ni,

20-CR, Oxidised |

1112

(600) |

0.87 |

| ˇˇ |

80-Ni,

20-CR, Oxidised |

2372

(1300) |

0.89 |

| Aluminium |

| ˇˇ |

Unoxidised |

77

(25) |

0.02 |

| ˇˇ |

Unoxidised |

212

(100) |

0.03 |

| ˇˇ |

Unoxidised |

932

(500) |

0.06 |

| ˇˇ |

Oxidised |

390

(199) |

0.11 |

| ˇˇ |

Oxidised |

1110

(599) |

0.19 |

| ˇˇ |

Oxidised at

599degC(1110degF) |

390

(199) |

0.11 |

| ˇˇ |

Oxidised at

599degC(1110degF) |

1110

(599) |

0.19 |

| ˇˇ |

Heavily

Oxidised |

200

(93) |

0.2 |

| ˇˇ |

Heavily

Oxidised |

940

(504) |

0.31 |

| ˇˇ |

Highly Polished |

212

(100) |

0.09 |

| ˇˇ |

Roughly Polished |

212

(100) |

0.18 |

| ˇˇ |

Commercial

Sheet |

212

(100) |

0.09 |

| ˇˇ |

Highly Polished

Plate |

440

(227) |

0.04 |

| ˇˇ |

Highly Polished

Plate |

1070

(577) |

0.06 |

| ˇˇ |

Bright Rolled

Plate |

338

(170) |

0.04 |

| ˇˇ |

Bright Rolled

Plate |

932

(500) |

0.05 |

| ˇˇ |

Alloy A3003,

Oxidised |

600

(316) |

0.4 |

| ˇˇ |

Alloy A3003,

Oxidised |

900

(482) |

0.4 |

| ˇˇ |

Alloy 1100-0 |

200-800

(93-427) |

0.05 |

| ˇˇ |

Alloy 24ST |

75

(24) |

0.09 |

| ˇˇ |

Alloy 24ST, Polished |

75

(24) |

0.09 |

| ˇˇ |

Alloy 75ST |

75

(24) |

0.11 |

| ˇˇ |

Alloy 75ST, Polished |

75

(24) |

0.08 |

| Bismuth, Bright |

176

(80) |

0.34 |

| Bismuth,

Unoxidised |

77

(25) |

0.05 |

| Bismuth, Unoxidised |

212

(100) |

0.06 |

| Brass |

| ˇˇ |

73% Cu, 27% Zn,

Polished |

476

(247) |

0.03 |

| ˇˇ |

73% Cu, 27% Zn,

Polished |

674

(357) |

0.03 |

| ˇˇ |

62% Cu, 37% Zn,

Polished |

494

(257) |

0.03 |

| ˇˇ |

62% Cu, 37% Zn,

Polished |

710

(377) |

0.04 |

| ˇˇ |

83% Cu, 17% Zn,

Polished |

530

(277) |

0.03 |

| ˇˇ |

Matte |

68

(20) |

0.07 |

| ˇˇ |

Burnished to Brown

Colour |

68 (20) |

0.4 |

| ˇˇ |

Cu-Zn, Brass

Oxidised |

392

(200) |

0.61 |

| ˇˇ |

Cu-Zn, Brass

Oxidised |

752

(400) |

0.6 |

| ˇˇ |

Cu-Zn, Brass

Oxidised |

1112

(600) |

0.61 |

| ˇˇ |

Unoxidised |

77

(25) |

0.04 |

| ˇˇ |

Unoxidised |

212

(100) |

0.04 |

| ˇˇ |

Cadmium |

77

(25) |

0.02 |

| Carbon |

| ˇˇ |

Lampblack |

77

(25) |

0.95 |

| ˇˇ |

Unoxidised |

77 (25) |

0.81 |

| ˇˇ |

Unoxidised |

212

(100) |

0.81 |

| ˇˇ |

Unoxidised |

932

(500) |

0.79 |

| ˇˇ |

Candle Soot |

250

(121) |

0.95 |

| ˇˇ |

Filament |

500

(260) |

0.95 |

| ˇˇ |

Graphitized |

212

(100) |

0.76 |

| ˇˇ |

Graphitized |

572

(300) |

0.75 |

| ˇˇ |

Graphitized |

932

(500) |

0.71 |

| Chromium |

100

(38) |

0.08 |

| Chromium |

1000

(538) |

0.26 |

| Chromium,

Polished |

302

(150) |

0.06 |

| Cobalt, Unoxidised |

932

(500) |

0.13 |

| Cobalt,

Unoxidised |

1832

(1000) |

0.23 |

| Columbium,

Unoxidised |

1500

(816) |

0.19 |

| Columbium,

Unoxidised |

2000

(1093) |

0.24 |

| Copper |

| ˇˇ |

Cuprous Oxide |

100

(38) |

0.87 |

| ˇˇ |

Cuprous

Oxide |

500

(260) |

0.83 |

| ˇˇ |

Cuprous Oxide |

1000

(538) |

0.77 |

| ˇˇ |

Black, Oxidised |

100

(38) |

0.78 |

| ˇˇ |

Etched |

100

(38) |

0.09 |

| ˇˇ |

Matte |

100

(38) |

0.22 |

| ˇˇ |

Roughly Polished |

100

(38) |

0.07 |

| ˇˇ |

Polished |

100

(38) |

0.03 |

| ˇˇ |

Highly Polished |

100

(38) |

0.02 |

| ˇˇ |

Rolled |

100

(38) |

0.64 |

| ˇˇ |

Rough |

100

(38) |

0.74 |

| ˇˇ |

Molten |

1000

(538) |

0.15 |

| ˇˇ |

Molten |

1970

(1077) |

0.16 |

| ˇˇ |

Molten |

2230

(1221) |

0.13 |

| ˇˇ |

Nickel Plated |

100-500

(38-260) |

0.37 |

| Dow Metal |

0.4-600

(-18-316) |

0.15 |

| Gold |

| ˇˇ |

Enamel |

212

(100) |

0.37 |

| ˇˇ |

Plate

(.0001) |

ˇˇ |

ˇˇ |

| ˇˇ |

Plate on .0005

Silver |

200-750

(93-399) |

.11-.14 |

| ˇˇ |

Plate on .0005

Nickel |

200-750

(93-399) |

.07-.09 |

| ˇˇ |

Polished |

100-500

(38-260) |

0.02 |

| ˇˇ |

Polished |

1000-2000 (538-1093) |

0.03 |

| Haynes Alloy

C, |

| ˇˇ |

Oxidised |

600-2000 (316-1093) |

.90-.96 |

| Haynes Alloy

25, |

| ˇˇ |

Oxidised |

600-2000 (316-1093) |

.86-.89 |

| Haynes Alloy

X, |

| ˇˇ |

Oxidised |

600-2000 (316-1093) |

.85-.88 |

| Inconel Sheet |

1000

(538) |

0.28 |

| Inconel Sheet |

1200

(649) |

0.42 |

| Inconel Sheet |

1400

(760) |

0.58 |

| Inconel X,

Polished |

75

(24) |

0.19 |

| Inconel B, Polished |

75 (24) |

0.21 |

| Iron |

| ˇˇ |

Oxidised |

212

(100) |

0.74 |

| ˇˇ |

Oxidised |

930

(499) |

0.84 |

| ˇˇ |

Oxidised |

2190

(1199) |

0.89 |

| ˇˇ |

Unoxidised |

212

(100) |

0.05 |

| ˇˇ |

Red Rust |

77

(25) |

0.7 |

| ˇˇ |

Rusted |

77

(25) |

0.65 |

| ˇˇ |

Liquid |

2760-3220 (1516-1771) |

.42-.45 |

| Cast

Iron |

| ˇˇ |

Oxidised |

390

(199) |

0.64 |

| ˇˇ |

Oxidised |

1110

(599) |

0.78 |

| ˇˇ |

Unoxidised |

212

(100) |

0.21 |

| ˇˇ |

Strong Oxidation |

40

(104) |

0.95 |

| ˇˇ |

Strong

Oxidation |

482

(250) |

0.95 |

| ˇˇ |

Liquid |

2795

(1535) |

0.29 |

| Wrought

Iron |

| ˇˇ |

Dull |

77 (25) |

0.94 |

| ˇˇ |

Dull |

660

(349) |

0.94 |

| ˇˇ |

Smooth |

100

(38) |

0.35 |

| ˇˇ |

Polished |

100

(38) |

0.28 |

| Lead |

| ˇˇ |

Polished |

100-500

(38-260) |

.06-.08 |

| ˇˇ |

Rough |

100

(38) |

0.43 |

| ˇˇ |

Oxidised |

100

(38) |

0.43 |

| ˇˇ |

Oxidised at

1100 |

100

(38) |

0.63 |

| ˇˇ |

Gray Oxidised |

100

(38) |

0.28 |

| Magnesium |

100-500

(38-260) |

.07-.13 |

| Magnesium Oxide |

1880-3140 (1027-1727) |

.16-.20 |

| Mercury |

32 (0) |

0.09 |

| Mercury |

77

(25) |

0.1 |

| Mercury |

100

(38) |

0.1 |

| Mercury |

212

(100) |

0.12 |

| Molybdenum |

100

(38) |

0.06 |

| Molybdenum |

500

(260) |

0.08 |

| Molybdenum |

1000

(538) |

0.11 |

| Molybdenum |

2000

(1093) |

0.18 |

| Molybdenum Oxidised

at 1000degF |

600

(316) |

0.8 |

| Molybdenum Oxidised

at 1000degF |

700

(371) |

0.84 |

| Molybdenum Oxidised

at 1000degF |

800

(427) |

0.84 |

| Molybdenum Oxidised

at 1000degF |

900

(482) |

0.83 |

| Molybdenum Oxidised

at 1000degF |

1000

(538) |

0.82 |

| Monel, Ni-Cu |

392

(200) |

0.41 |

| Monel, Ni-Cu |

752

(400) |

0.44 |

| Monel, Ni-Cu |

1112

(600) |

0.46 |

| Monel, Ni-Cu

Oxidised |

68 (20) |

0.43 |

| Monel, Ni-Cu Oxid.

at 1110degF |

1110

(599) |

0.46 |

| Nickel |

| ˇˇ |

Polished |

100

(38) |

0.05 |

| ˇˇ |

Oxidised |

100-500

(38-260) |

.31-.46 |

| ˇˇ |

Unoxidised |

77

(25) |

0.05 |

| ˇˇ |

Unoxidised |

212

(100) |

0.06 |

| ˇˇ |

Unoxidised |

932

(500) |

0.12 |

| ˇˇ |

Unoxidised |

1832

(1000) |

0.19 |

| ˇˇ |

Electrolytic |

100

(38) |

0.04 |

| ˇˇ |

Electrolytic |

500

(260) |

0.06 |

| ˇˇ |

Electrolytic |

1000

(538) |

0.1 |

| ˇˇ |

Electrolytic |

2000

(1093) |

0.16 |

| Nickel Oxide |

1000-2000 (538-1093) |

.59-.86 |

| Palladium Plate

(.00005 on .0005 silver) |

200-750

(93-399) |

.16-.17 |

| Platinum |

100

(38) |

0.05 |

| Platinum |

500

(260) |

0.05 |

| Platinum |

1000

(538) |

0.1 |

| Platinum,

Black |

100

(38) |

0.93 |

| Platinum,

Black |

500

(260) |

0.96 |

| Platinum,

Black |

2000

(1093) |

0.97 |

| Platinum Oxidised at

1100 |

500

(260) |

0.07 |

| Platinum Oxidised at

1100 |

1000

(538) |

0.11 |

| Rhodium Flash

(0.0002 on 0.0005 Ni) |

200-700

(93-371) |

.10-.18 |

| Silver |

| ˇˇ |

Plate (0.0005 on

Ni) |

200-700

(93-371) |

.06-.07 |

| ˇˇ |

Polished |

100

(38) |

0.01 |

| ˇˇ |

Polished |

500

(260) |

0.02 |

| ˇˇ |

Polished |

1000

(538) |

0.03 |

| ˇˇ |

Polished |

2000

(1093) |

0.03 |

| Steel |

| ˇˇ |

Cold

Rolled |

200

(93) |

.75-.85 |

| ˇˇ |

Ground

Sheet |

1720-2010 (938-1099) |

.55-.61 |

| ˇˇ |

Polished

Sheet |

100

(38) |

0.07 |

| ˇˇ |

Polished

Sheet |

500

(260) |

0.1 |

| ˇˇ |

Polished

Sheet |

1000

(538) |

0.14 |

| ˇˇ |

Mild Steel,

Polished |

75

(24) |

0.1 |

| ˇˇ |

Mild Steel,

Smooth |

75

(24) |

0.12 |

| ˇˇ |

Mild

Steel,liquid |

2910-3270 (1599-1793) |

0.28 |

| ˇˇ |

Steel,

Unoxidised |

212

(100) |

0.08 |

| ˇˇ |

Steel, Oxidised |

77

(25) |

0.8 |

| Steel

Alloys |

| ˇˇ |

Type 301, Polished |

75

(24) |

0.27 |

| ˇˇ |

Type 301,

Polished |

450

(232) |

0.57 |

| ˇˇ |

Type 301, Polished |

1740

(949) |

0.55 |

| ˇˇ |

Type 303, Oxidised |

600-2000 (316-1093) |

.74-.87 |

| ˇˇ |

Type 310, Rolled |

1500-2100 (816-1149) |

.56-.81 |

| ˇˇ |

Type 316,

Polished |

75

(24) |

0.28 |

| ˇˇ |

Type 316,

Polished |

450

(232) |

0.57 |

| ˇˇ |

Type 316,

Polished |

1740

(949) |

0.66 |

| ˇˇ |

Type 321 |

200-800

(93-427) |

.27-.32 |

| ˇˇ |

Type 321

Polished |

300-1500 (149-815) |

.18-.49 |

| ˇˇ |

Type 321 w/BK Oxide |

200-800

(93-427) |

.66-.76 |

| ˇˇ |

Type 347, Oxidised |

600-2000 (316-1093) |

.87-.91 |

| ˇˇ |

Type 350 |

200-800

(93-427) |

.18-.27 |

| ˇˇ |

Type 350

Polished |

300-1800 (149-982) |

.11-.35 |

| ˇˇ |

Type 446, Polished |

300-1500 (149-815) |

.15-.37 |

| ˇˇ |

Type 17-7

PH |

200-600

(93-316) |

.44-.51 |

| ˇˇ |

Type 17-7 PH

Polished |

300-1500 (149-815) |

.09-.16 |

| ˇˇ |

Type

C1020,Oxidised |

600-2000 (316-1093) |

.87-.91 |

| ˇˇ |

Type PH-15-7

MO |

300-1200 (149-649) |

.07-.19 |

| Stellite, Polished |

68

(20) |

0.18 |

| Tantalum,

Unoxidised |

1340

(727) |

0.14 |

| Tantalum,

Unoxidised |

2000

(1093) |

0.19 |

| Tantalum,

Unoxidised |

3600

(1982) |

0.26 |

| Tantalum,

Unoxidised |

5306

(2930) |

0.3 |

| Tin,

Unoxidised |

77

(25) |

0.04 |

| Tin,

Unoxidised |

212

(100) |

0.05 |

| Tinned Iron,

Bright |

76

(24) |

0.05 |

| Tinned Iron,

Bright |

212

(100) |

0.08 |

| Titanium |

| ˇˇ |

Alloy C110M,Polished |

300-1200 (149-649) |

.08-.19 |

| ˇˇ |

Oxidised at

538degC(1000degF) |

200-800

(93-427) |

.51-.61 |

| ˇˇ |

Alloy

Ti-95A,Oxidised at 538degC(1000degF) |

200-800

(93-427) |

.35-.48 |

| ˇˇ |

Anodized onto SS |

200-600

(93-316) |

.96-.82 |

| Tungsten |

| ˇˇ |

Unoxidised |

77

(25) |

0.02 |

| ˇˇ |

Unoxidised |

212

(100) |

0.03 |

| ˇˇ |

Unoxidised |

932

(500) |

0.07 |

| ˇˇ |

Unoxidised |

1832

(1000) |

0.15 |

| ˇˇ |

Unoxidised |

2732

(1500) |

0.23 |

| ˇˇ |

Unoxidised |

3632

(2000) |

0.28 |

| ˇˇ |

Filament

(Aged) |

100

(38) |

0.03 |

| ˇˇ |

Filament

(Aged) |

1000

(538) |

0.11 |

| ˇˇ |

Filament (Aged) |

5000

(2760) |

0.35 |

| Uranium Oxide |

1880

(1027) |

0.79 |

| Zinc |

| ˇˇ |

Bright,

Galvanised |

100

(38) |

0.23 |

| ˇˇ |

Commercial 99.1% |

500

(260) |

0.05 |

| ˇˇ |

Galvanised |

100

(38) |

0.28 |

| ˇˇ |

Oxidised |

500-1000 (260-538) |

0.11 |

| ˇˇ |

Polished |

100

(38) |

0.02 |

| ˇˇ |

Polished |

500

(260) |

0.03 |

| ˇˇ |

Polished |

1000

(538) |

0.04 |

| ˇˇ |

Polished |

2000

(1093) |

0.06 |

|

|

|

|

|

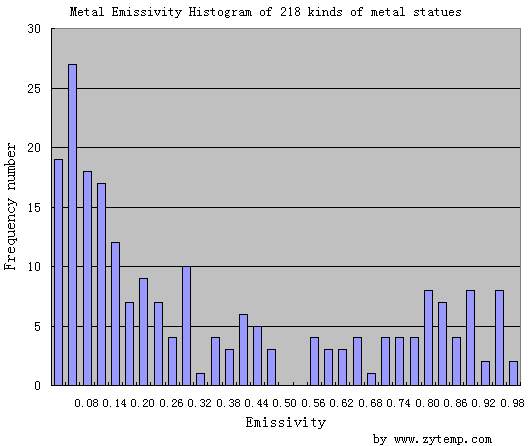

金属的EMS直方图

|